MillTraj Liner Design Software

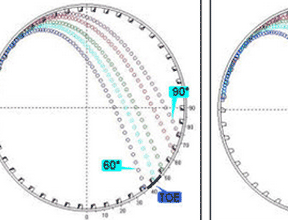

MillTraj utilises a model based on the correct analytical solution of the physics of motion of particles to predict the motion of the outermost grinding media in a rotary grinding mill, as affected by the design of the lining. This provides a fundamental guideline to the design of efficient mill liners. The theoretical basis of the software has been published in the international literature. The theoretical understanding behind this has been further investigated with advanced X-ray analysis techniques, as given in the papers on charge motion in rotary mills. Read more about our theory.

- Over 200 licenses worldwide

- Simple to use with known mill parameters

- Convenient on laptop for on-site marketing of liners to clients

- Informs selection of lifter angles and heights related to: mill application, mill size, mill speed, filling and ball size.

Why use MillTraj?

Poor liner design has a detrimental affect on milling performance and on liner life 2,3. This results in a loss of revenue and increased operational costs. Poor milling performance can result in excess power usage and decreased recovery of the valuable minerals. Excess liner wear results in exorbitant liner materials costs, and excessive downtime which reduces mill availability and impacts on plant throughput. For a plant with a number of mills this also entails the employment of extra mill relining staff and the risks and costs associated with frequent relining.

Advanced Demonstrations Videos

If you are interested in viewing additional functionality, the videos below provide additional information.

Modeling variable speeds and High Low Lifters View Video: View Video

Modeling Recessed Lifters and measuring angle from face: View Video